A box containing gears. Add two constraints using the -button.

Gearbox Design Team1 4 Project4

V πdn60000 πx50x100060000 236 ms.

. A material is to be selected by doing intensive research on the properties of the various materials. You must learn choose the specific materials to produce any details of assembly unit and choose right method for producing. Graph 1723a Friction torque at various temperatures for nitrile rubber.

Tsat operating speed of pinion shaft speed 017 x 695236 130244 Nm. However the gearbox designer and assembly technician share responsibility for incorporating this optimum positioning in the gearbox. With the relative speed of one member of a pair of gears known the speed of the mating gear is easily obtained by the equation.

In fact the name itself defines what it is. Stan 0 4 7 sec 0 4t 7 u 0 sec 0 for. The first step in the gearbox design process is to select the material.

Define positioning The next step is to define the positioning of the shafts. Chercher les emplois correspondant à Gearbox design calculations powerpoint ou embaucher sur le plus grand marché de freelance au monde avec plus de 21 millions demplois. The Vex 393 was a.

Linscription et faire des offres sont gratuits. Content uploaded by Sandip A Kale. Search for jobs related to Gearbox design calculations powerpoint or hire on the worlds largest freelancing marketplace with 20m jobs.

Gear ratio chosen 7561. Gearbox Design Calculations Powerpoint. Prelminary Design - Tamiya 72005 6-speed gearbox.

Roller chain transmission transmission 14 output speed 12083 4 3021. Number of gears on the shafts should not be more than 3. A material is to be selected keeping in mind the various parameters like strength.

Its free to sign up and bid on jobs. Introduction to types of gears gear. This design was conducted by the creation and implementation of a Microsoft Excel spreadsheet to create an equation driven design interface program for the design of each component of the gearbox reducer.

Its high torque and low speed are often used in manipulators. Each of the chapters will deal with a-specific problem which is encountered during the design phases and during operation. The most basic definition of a gearbox is that it is a contained gear train or a mechanical unit or component consisting of a series of integrated gears within a housing.

For this select Positioning in the system tree. Basics about Gear Box Design for Machine Tools. The Window Motor is a motor that comes with a worm gearbox attached.

FPrinciples to be followed to obtain optimum design. It is preferable to have nmax ninput nmin in all the stages except in the first stage. Where Np and NGNumber of teeth in pinion and gear.

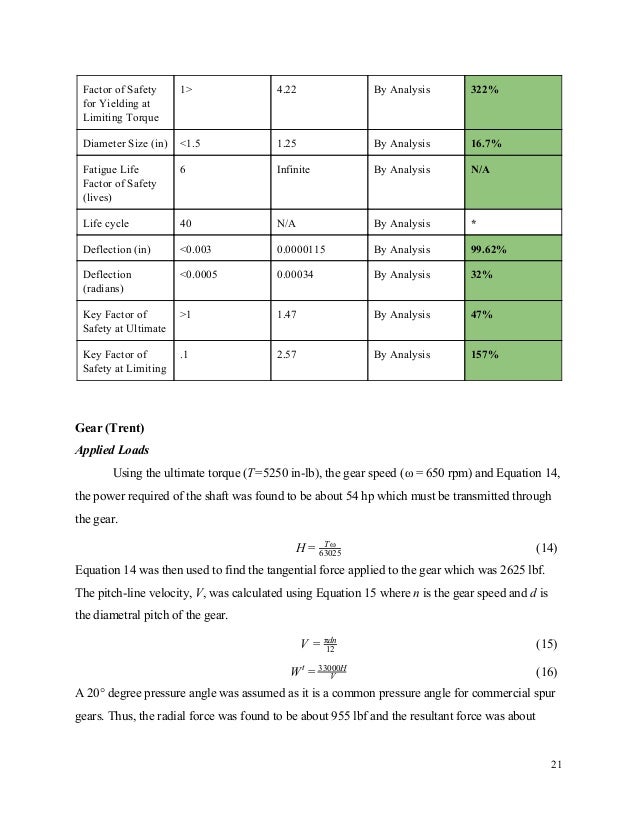

Due to the worm drive they cannot be backdriven a capability that is desirable for some applications. The task for this team was to design a spur gearbox reducer which could handle a 10 horsepower input power with a gear ratio of 35 with 1 variation. Design of gear boxes for machine tool applications maximum three stages and twelve speeds requirements of.

S type oil seal Shaft diameter 50 mm speed 1000 rpm. The operating Velocity V πx45x295060000 695 ms. The aim of this guide is to provide instruction on how best to accomplish this.

The main purpose of this project GearboxCalculation is determine and choosing the main parameters of a car and the design gearbox unit. This book will attempt to follow the design sequence used by the author during the design of a manually operated automotive gearbox. Minimum speed 133 ft s.

Speed Limits OM I 141 Max operating speed V MO. Np and nGRevolutions per minute rpm ofpi- nion and gearrespectively. Number of gears on the last shaft spindle should be minimum.

Of teeth t n is given by the following calculation. In the most basic sense a gearbox functions like any system of gears. Design of mechanical systems dms design of gear box.

The designer must provide shimming dimen-sions that are easy to measure in order to aid the fittertechni-cian in assembling the overall gearbox. The pre-designed templates come in a variety of different layouts each of which are just perfect for capturing the attention of your audience. This course is structured with an introduction to elements of Gear box and more focused towards Industrial applications.

The calculation program for the gear strength calculation can be selected if available. It alters torque and speed between. This chapter begins with a comparison of the merits of spiral bevel.

The presentation explains how to design a gearbox. Spur gear design input characteristics.

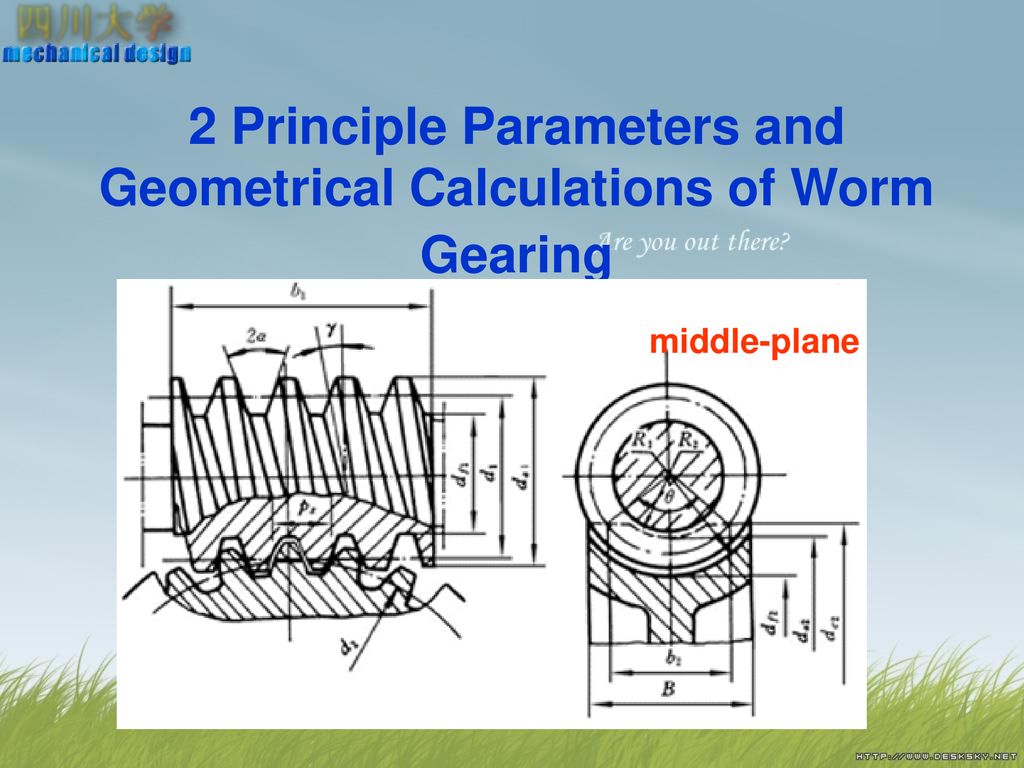

Chapter 11 Design Of Worm Gearing Ppt Download

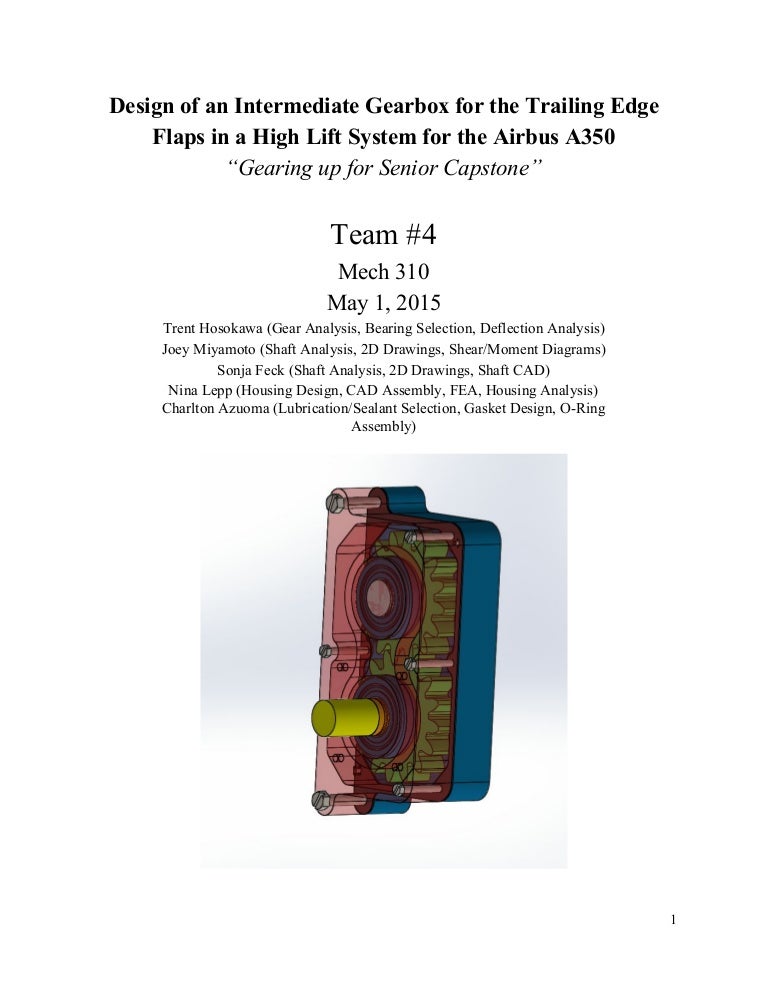

Gearbox Design Team1 4 Project4

Gearbox Design Team1 4 Project4

Gearbox Calculation Car Construction

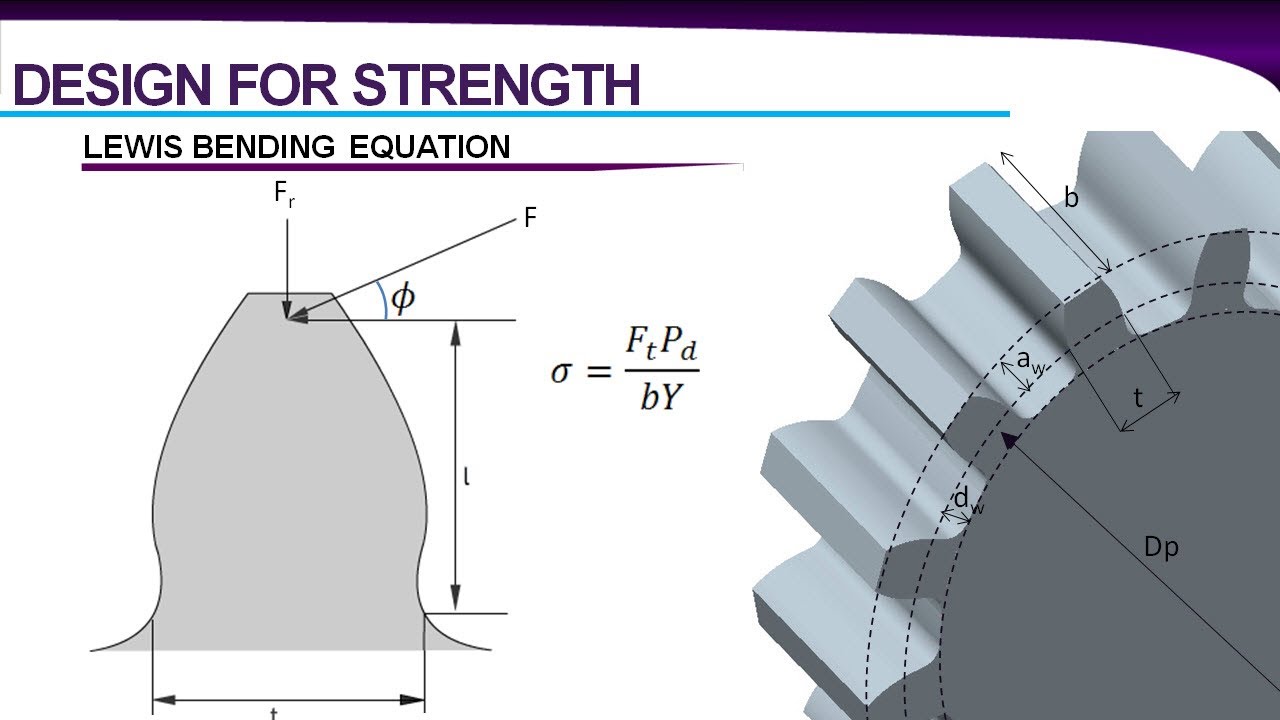

Gear Design Spur Gears Youtube

0 comments

Post a Comment